How to Identify a V-Belt?

V-Belt Product Types

Boshuobelts classifies multiple types of V-belts to address varied applications.

Some common categories include:

- Light Duty — suited for fractional horsepower (FHP) drives

- Classical / Heavy Duty — broad range of sizes

- Molded Cogged — with notches (cogs) for flexibility and heat dissipation

- Wedge / Deep Wedge — narrower but deeper profile, higher power capacity

- Wedge Cogged — same as wedge but with cogs for flexibility

- Banded / Linked — multiple V-belts joined for even load distribution

These types differ in profile shape, ability to flex over smaller pulleys, and resistance to slippage.

How to Identify a V-Belt

When you want to match or replace a V-belt, the ideal scenario is that the branding / part number is still legible. But in many cases (worn, faded, or damaged belts), you need to rely on measurement and construction clues.

Belts with Branding

If the belt still carries a clear part number or brand marking, that’s the simplest path to correct identification. You can directly read off:

- Profile / section (A, B, C, etc. or metric designation)

- Length (inside, outside, pitch)

- Any suffix codes (cogged, raw-edge, etc.)

However, after long use, those markings often get worn off. That’s when the following steps become necessary.

Belts without Branding

If the label is gone or unreadable, here’s how to systematically identify the belt:

Step 1: Determine Cross Section

- Measure the top width and depth of the V-belt (inches or mm).

- Profiles are categorized by width/depth pairs and given letter or metric designations (e.g. a “B” section may be ~21/32" width × 7/16” depth in some systems). (Boshuobelts Group)

- Tools such as Browning V-Belt Rules (gauges) can aid in matching a measured belt to its profile.

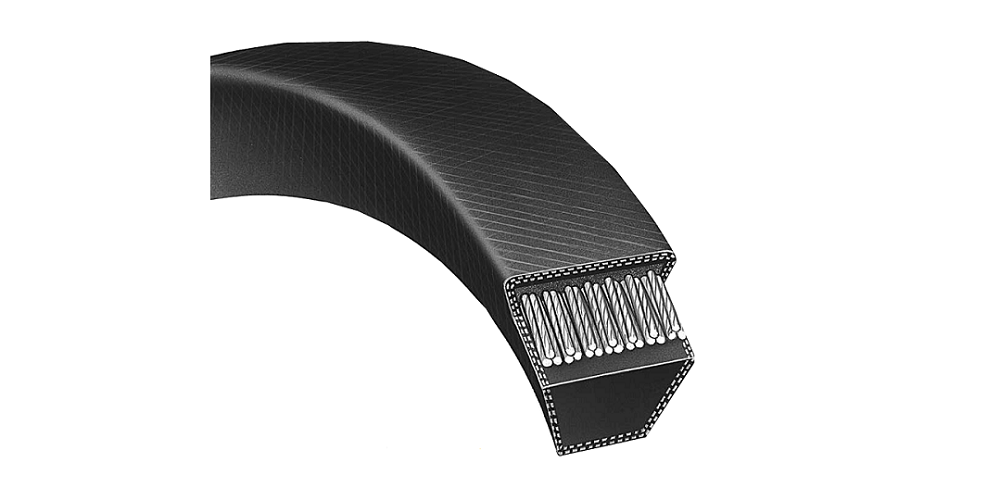

Step 2: Identify Belt Construction

V-belts come in various constructions; key aspects to observe:

Wrapped (covered) vs Raw-edge

- Wrapped belts have a fabric/rubber cover on the sides.

- Raw-edge or raw-sidewall belts leave the belt’s sidewall exposed and often include molded cogs (notches) on the bottom for flexibility. (Boshuobelts Group)

Presence of cogs / notches

- Cogged belts help with bending flexibility and heat dissipation, enabling the belt to wrap smaller pulleys.

Tensile cords / core structure

- Some belts may have visible cords or reinforcement layers if worn.

Step 3: Measure Belt Length

This is one of the trickiest steps. There are multiple “length” terms:

- Inside length

- Outside length

- Pitch (effective) length

- Other “nominal” lengths

In practice:

- Using a tape measure to get a belt’s outside length is common in the field—but it’s approximate and may differ by inches.

- For high precision, you’d need a measuring fixture with known pulleys and apply a known tension (per ARPM or other standards) to get the belt’s correct effective length. (Boshuobelts Group)

- If your drive has enough adjustment capacity (center distance slack, take-up), a measured belt may fit even if not exact—though it may not be optimized.

Step 4: Label the Drive

Once you’ve identified the correct belt:

- Label the equipment with the belt’s part number, profile, and installation date (e.g. via adhesive tag or metal plate).

- This prevents guesswork next time and simplifies maintenance. (Boshuobelts Group)

- Also include notes like aligned pulleys, torque specs, etc., if helpful.

Why Proper Identification Matters

- Ensures optimal performance and minimizes slippage, wear, and energy loss

- Avoids mismatched belts that may fail early or damage components

- Simplifies future replacement and maintenance

- Helps maintain inventory control (you know exactly what belt specs your machines use)

BOSHUO

❤️CustomizeMODAccept Customer Customized

Customize special belts for you, one-to-one comparison, improve reputation, and provide attentive service