Product Catalog 2025

Now Available for Download

BOSHUO Product Catalog 2025

Download our comprehensive belting catalogue to learn more about our company, products and more.

Customer Success

Your success is our priority

BOSHUO Customer Success

Building lasting partnerships through exceptional service and support.

Sustainability Report

Service staff can provide

BOSHUO Sustainability Report 2025

Download our comprehensive sustainability report showcasing our environmental initiatives and progress.

Global Presence

Connecting the world through our network

BOSHUO Global Presence

Serving customers worldwide with excellence and reliability.

Our Products

BoShuo offers a wide variety of standard items and special products designed to satisfy specific customer requirements.Here below you can find our main products. To discover all our range, click PRODUCTS into the menu.

TIMING BELTS

BSSYNC® TITANIUM

High-performance timing belts with titanium reinforcement

BSSYNC® RPP AND RPP DD

Robust power transmission solutions for demanding applications

BSLINEAR QST

Linear motion timing belts for precision applications

BSPOWER2

Enhanced power transmission with superior durability

BSSYNC® TO CNC

High-accuracy timing belts specifically designed for CNC machines and 3D printers,ensuring precise positioning and smooth motion control in digital fabrication.

BSSYNC® TO HTD

HTD (High Torque Drive) timing belts with curved tooth profile for superior power transmission, reduced backlash, and excellent load distribution.

V-BELTS

CLASSICAL V-BELTS

Standard V-belts for general industrial applications

NARROW V-BELTS

Space-saving design with high power transmission

VARIABLE SPEED BELTS

Flexible speed control for variable applications

COGGED V-BELTS

Enhanced flexibility and heat dissipation

V-RIB BELTS

AUTOMOTIVE BELTS

High-performance belts for automotive applications

INDUSTRIAL MULTI-RIB

Heavy-duty multi-rib belts for industrial use

MICRO-V BELTS

Compact design for space-constrained applications

STRETCH-FIT BELTS

Easy installation without tensioning adjustments

SPECIAL & FABRICATED BELTS

CUSTOM FABRICATED

Specially designed belts for unique applications

ENDLESS BELTS

Seamless construction for smooth operation

SPECIALTY MATERIALS

Exotic materials for extreme conditions

PROTOTYPE DEVELOPMENT

Custom development for new applications

CUSTOM SOLUTIONS

Tailored products designed to meet your specific industrial requirements.

QUALITY Assurance

All products undergo rigorous testing to ensure superior performance and durability.

EXPERT Support

Our technical team provides comprehensive support throughout your project lifecycle.

FAQ

We've compiled the most frequently asked questions by customers

What is a transmission belt?

A transmission belt is a mechanical component that transfers power between two pulley shafts. It transmits power from the driving pulley to the driven pulley through friction or meshing force, enabling power transmission in mechanical equipment.

- Timing belt: Achieves precise transmission through tooth profile

- V-belt: Provides strong friction through wedge-shaped cross-section

- Flat belt: Suitable for high-speed light-load applications

- Multi-rib belt: Combines advantages of V-belts and flat belts

Related tags:

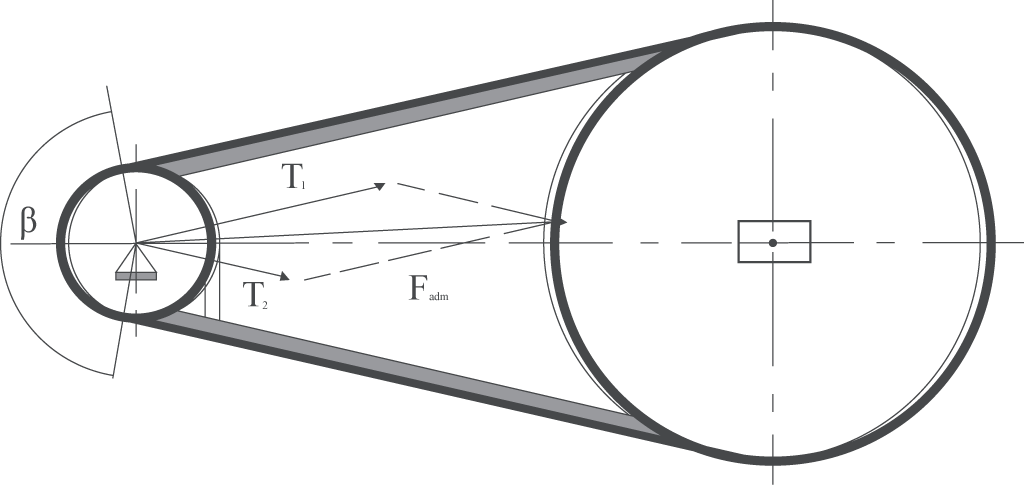

Transmission belt between two pulley shafts

This is the basic definition of a transmission belt. A belt drive system consists of three main components: the driving pulley, the driven pulley, and the transmission belt. The driving pulley connects to the power source, the driven pulley connects to the load, and the belt transmits the power.

- Driving pulley: Connects to motor or engine

- Driven pulley: Connects to working machinery

- Tension pulley: Adjusts belt tension

- Guide pulley: Changes belt running direction

Top global V-belt brands?

World-renowned V-belt brands include: Gates, Optibelt, Dayco, Megadyne, PIX, etc. These brands lead in quality, technological innovation, and market share.

- Gates - USA, world's largest belt manufacturer

- Optibelt - Germany, expert in high-end industrial belts

- Dayco - Italy, leader in automotive and industrial belts

- Megadyne - Italy, provider of innovative transmission solutions

Related tags:

How to calculate belt tension?

Belt tension calculation considers multiple factors: transmitted power, pulley diameter, belt speed, friction coefficient, etc. The basic formula is: T1/T2 = e^(μα), where T1 and T2 are tight-side and slack-side tensions, μ is friction coefficient, and α is wrap angle.

- Initial tension: Pre-tension during installation

- Working tension: Actual tension during operation

- Maximum tension: Allowable maximum tension value

- Tension measurement: Using tension meter

Related tags:

What is the service life of transmission belts?

The service life of transmission belts depends on multiple factors: working environment, load conditions, maintenance, etc. Generally, industrial belts last 1-3 years, while automotive belts last 60,000-100,000 kilometers.

- Environmental factors: temperature, humidity, chemical corrosion

- Load factors: power level, impact loads

- Maintenance factors: regular inspection, timely adjustment

- Quality factors: material quality, manufacturing process

Related tags:

What are the applications of rubber belts?

Rubber belts are widely used in various industries: automotive (engine accessory drives), textile (spinning and weaving), food (conveying and packaging), agricultural machinery (harvesting and seeding), etc.

- Automotive: AC compressors, generators, water pumps

- Industrial equipment: fans, pumps, compressors

- Agricultural machinery: tractors, harvesters, seeders

- Household appliances: washing machines, dryers, vacuum cleaners

What is a drive pulley?

A drive pulley is the wheel in a transmission system that connects to the power source, typically mounted on the output shaft of a motor or engine. It transmits power to the driven pulley via the belt, enabling power transfer and speed variation.

- Material selection: cast iron, steel, aluminum alloy

- Surface treatment: zinc plating, blackening, anodizing

- Groove design: standard profiles like A, B, C types

- Dynamic balancing: required for high-speed operation

Related tags:

What types of belts are used in the automotive industry?

The automotive industry primarily uses these belt types: multi-rib belts (serpentine belts), timing belts, V-belts, and flat belts. Each type has specific applications and technical requirements.

- Multi-rib belts: Engine accessory drives (AC, alternator, power steering)

- Timing belts: Engine timing systems (camshaft, balance shaft)

- V-belts: Older vehicle models for fan and alternator drives

- Flat belts: Light-duty applications in special cases

Related tags:

Didn't find the answer you're looking for?

Our technical experts are ready to provide professional consulting services

Blog

Discover our latest posts

Are you interested in our products?

Ask our experts for more information

Click to view detailed technical drawings

Or contact us through:

Product&Industries Consultation

Our team will provide you with professional quotations, consultations, and technical services to meet your needs.