Our Industries

Our belts are designed to working efficiently in any kind of machine, serving most of the industrial sectors such as textile, chemical, wood and many others. Discover all of them.

ALUMINIUM

AUTOMOTIVE

CERAMIC AND MORE

APPLIANCE

CONSTRUCTION

ELEVATORS

ENERGY

FITNESS

FOOD

AGRICULTURE

MACHINE TOOLS

MATERIAL HANDLING

MEDICAL INDUSTRY

PACKAGING

PAPER AND PRINT

RECYCLING

AUTOMATION

TEXTILE

20+

Product&Industries Consultation

5000+

Customer Cases

50+

Countries/Regions

25+

Years of Experience

FAQ

We've compiled the most frequently asked questions by customers

What is a transmission belt?

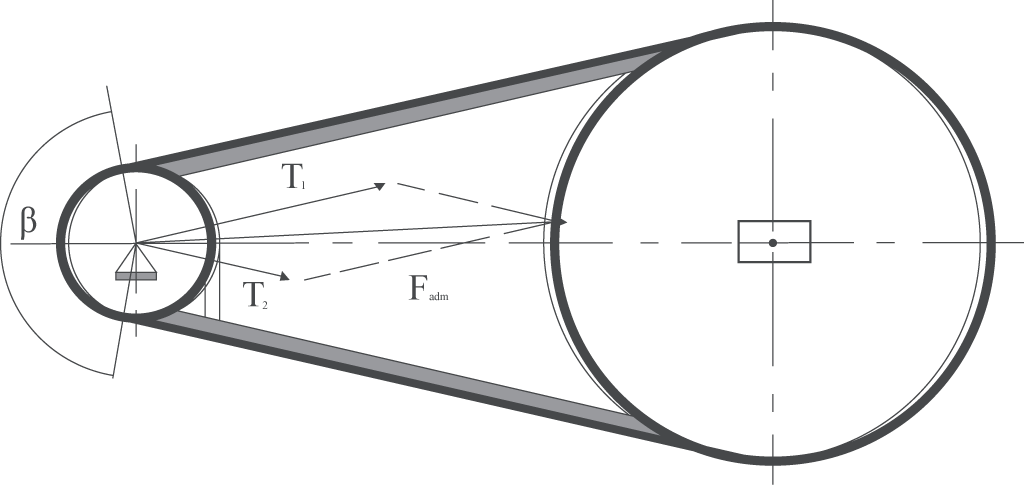

Transmission belt between two pulley shafts

Top global V-belt brands?

How to calculate belt tension?

What is the service life of transmission belts?

What are the applications of rubber belts?

What is a drive pulley?

What types of belts are used in the automotive industry?

Didn't find the answer you're looking for?

Our technical experts are ready to provide professional consulting services

Blog

Discover our latest posts

Are you interested in our products?

Ask our experts for more information

Inquiry submitted successfully! Our expert will contact you within 24 hours.

Product&Industries Consultation

Our team will provide you with professional quotations, consultations, and technical services to meet your needs.