The Common Types and Sizes of V-Belts

Common Types of V-Belts: Sizes, Applications & Selection Guide

Published Sep 27, 2025 • Reading time: 6 min

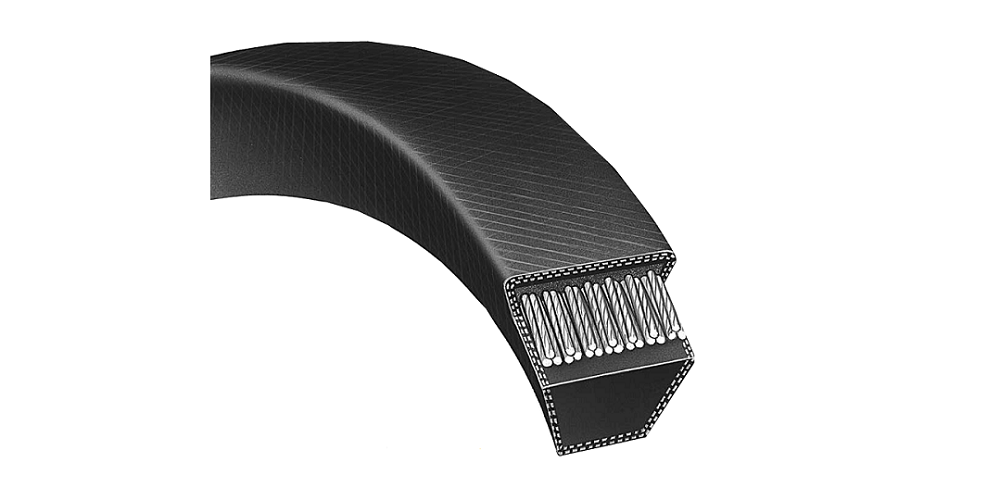

What Is a V-Belt?

A V-belt is a common power-transmission belt used across industrial, agricultural, and automotive equipment. The belt’s trapezoidal "V" cross-section fits into pulley grooves and creates a secure wedge action to reduce slippage.

Why Choosing The Right V-Belt Matters

Selecting the proper V-belt improves machine efficiency, reduces wear, and extends service life. Incorrect selection can cause premature failure, increased energy use, and unplanned downtime.

Main Types of V-Belts

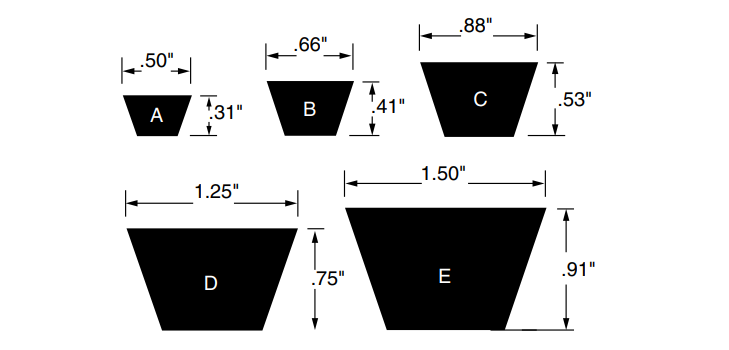

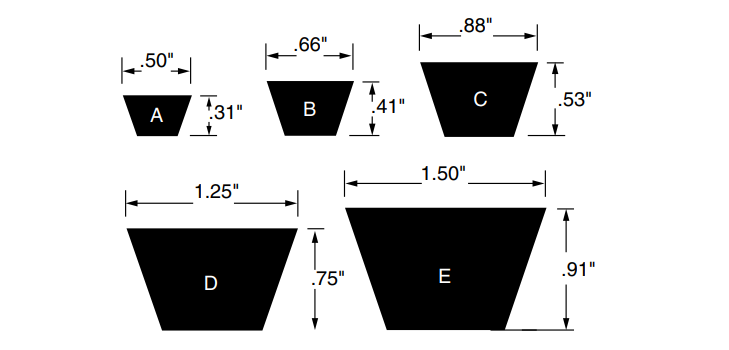

1. Classical V-Belts

The conventional V-belt is the most common type and has been around the longest. The Initial classical V design replaced leather belts by taking over their applications in various industries, such as agriculture, ventilation, and industrial machinery. Classical V-belts can cover a load range from fractional(less than 1 HP) to 500 horsepower. They are less efficient than narrow V-belts and generally contribute to higher bearing loads. However, classical V-belts have a high tolerance for poor operating conditions. The general part number format is the cross-section size and the inside length in inches ( e.g., B50 is a B section of 50 inches inside measurement). General cross-sectional dimensions that are used in the US are shown below.

- Identification: A, B, C, D, E sections + internal length in inches (e.g., B50).

- Features: Traditional design, flexible, suitable for a wide power range.

- Applications: Fans, conveyors, agriculture equipment, HVAC drives.

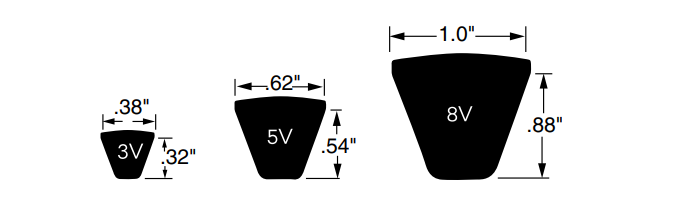

2. Narrow V-Belts (Wedge Belts)

- Identification: 3V, 5V, 8V with outside length (e.g., 5V500).

- Features: Deeper profile, higher power density, works well where space is limited.

- Applications: Compressors, pumps, heavy-duty and high-speed machinery.

Note: An "X" suffix (e.g., 5VX) typically indicates a cogged (notched) belt for better flexibility and cooling.

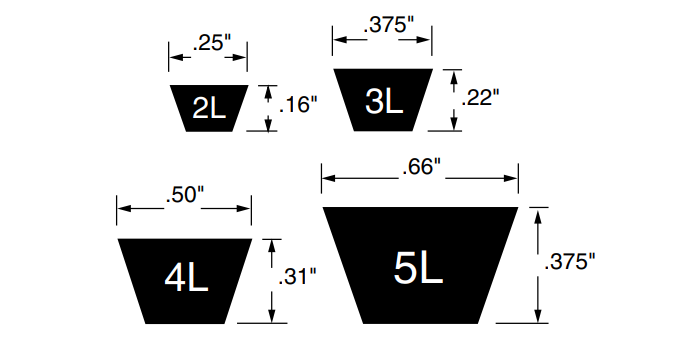

3. Fractional Horsepower (FHP) V-Belts

- Identification: 2L, 3L, 4L, 5L (e.g., 3L300).

- Features: Lightweight, economical, designed for low-power use.

- Applications: Household appliances, small fans, light equipment.

Quick Comparison

| Type | Example | Power | Applications | Advantage |

|---|---|---|---|---|

| Classical V-Belt | B50 | Low–Medium | Fans, conveyors, agriculture | Versatile & common |

| Narrow V-Belt | 5V500 | Medium–High | Compressors, pumps, heavy-duty | Higher efficiency |

| FHP V-Belt | 3L300 | Low | Small appliances, fans | Lightweight & affordable |

How to Choose the Right V-Belt

- Power & Speed: Match horsepower and RPM.

- Pulley & Shaft: Consider pulley size and belt length.

- Environment: Heat, dust, oil, moisture matter.

- Load Type: Continuous vs shock loads.

- Efficiency vs Cost: Narrow belts are efficient but more expensive.

Conclusion

V-belts remain a cost-effective and reliable choice for many power transmission applications. Knowing the differences—classical, narrow, and FHP—helps you choose the right solution for performance and efficiency.

📌 Next Steps

- Contact us for expert help

- Download V-Belt Size Chart

BOSHUO

❤️CustomizeMODAccept Customer Customized

Customize special belts for you, one-to-one comparison, improve reputation, and provide attentive service